Back in Dec 2020, I bought a RTW shirt dress. At the time, this felt like an extremely bougie purchase – $300 for dress? Yikes. I liked the dress so much I bought it in another colour way the following year. This brand clearly designed for a shape larger than a B cup – because this button up shirt never gaped, ever. And when it started to come apart at the seams, it was an easy decision to cut it up and turn it into a pattern to replace it.

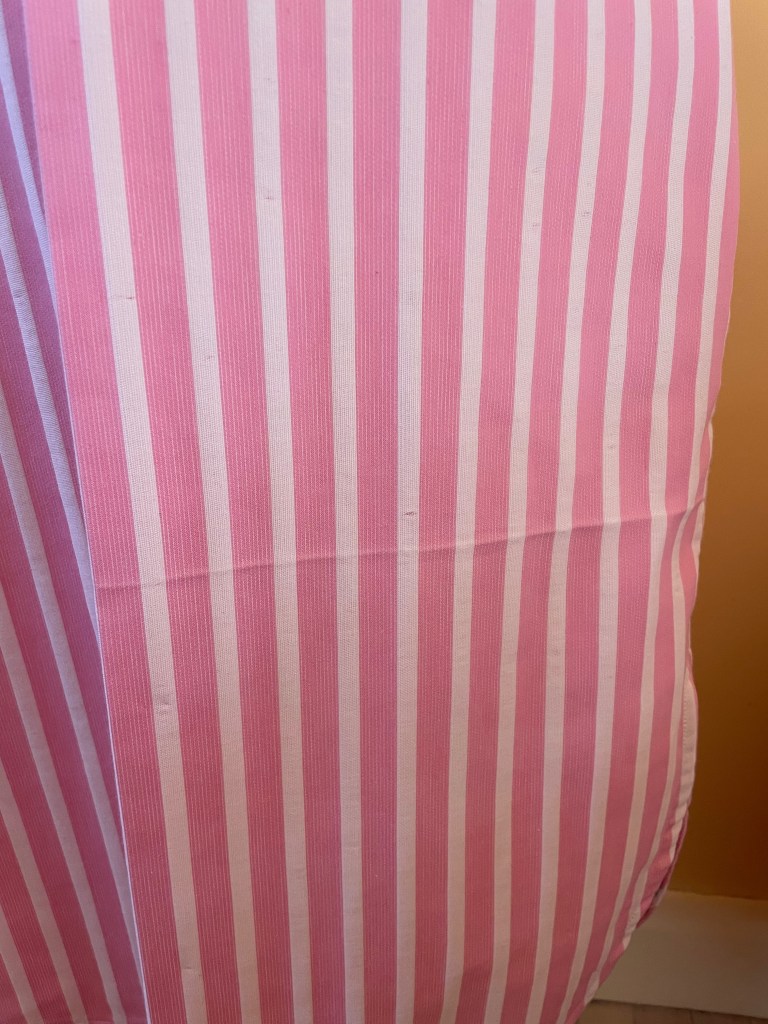

I first reached for a delicious reversible pink and white cotton fabric to recreate this dress. Purchased from Mendel Goldberg quite a number of years before.

But unfortunately, the length I received had a permanent crease line down the centre of the length, also also a number of faults in the fabric – neither of which I saw until I had started to cut out the fabric. I tried to place the faults along the waistline so they’d be hidden by the tie, but alas, I couldn’t cut out the sleeves around the fault line… and then I realised I had a fault that was highly visible on the front bodice piece. So it was game over for that, and an expensive lesson learnt to better inspect my fabric before cutting into it – which I feel I shouldn’t have to do when I’m buying notably expensive pieces of fabric.

But also, the original RTW dress was made of a heavy but drapey 100% tencil fabric, and I think the structured nature of the pink cotton meant it ultimately wouldn’t have worked as well for this style. This partially constructed dress remains on a hanger in my sewing room, where I’m contemplating how I might save it and make it a short sleeve blouse somehow? We’ll see.

My second attempt made it to the finish line! I used a very poorly behaved silk twill (all twills are badly behaved to sew with, lets be honest), that I underlined with a white silk CDC. Which is honestly making things about as hard as it can get for myself. With much frustration and on-the-fly problem solving, this dress turned out ok! The combined weights of the silk together make it feel like heavyweight silk, which is honestly such a beautifully tactile experience to wear.

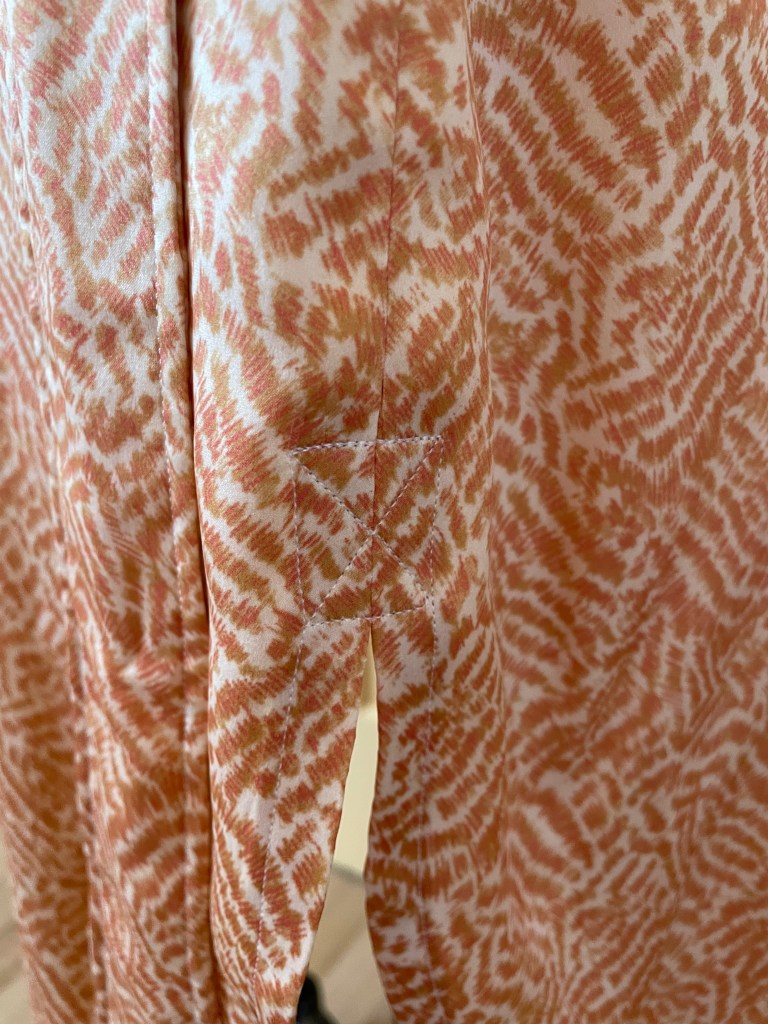

The original RTW dress ended up ripping along the side split, so I’ve done some extra re-enforcing at this seam junction. One of the challenges I have good photos of is how much more the silk twill dropped under its own weight as compared to the underlining, which required a rather large intervention of unpicking the basting threads, and re-attaching to remove the excess fabric.

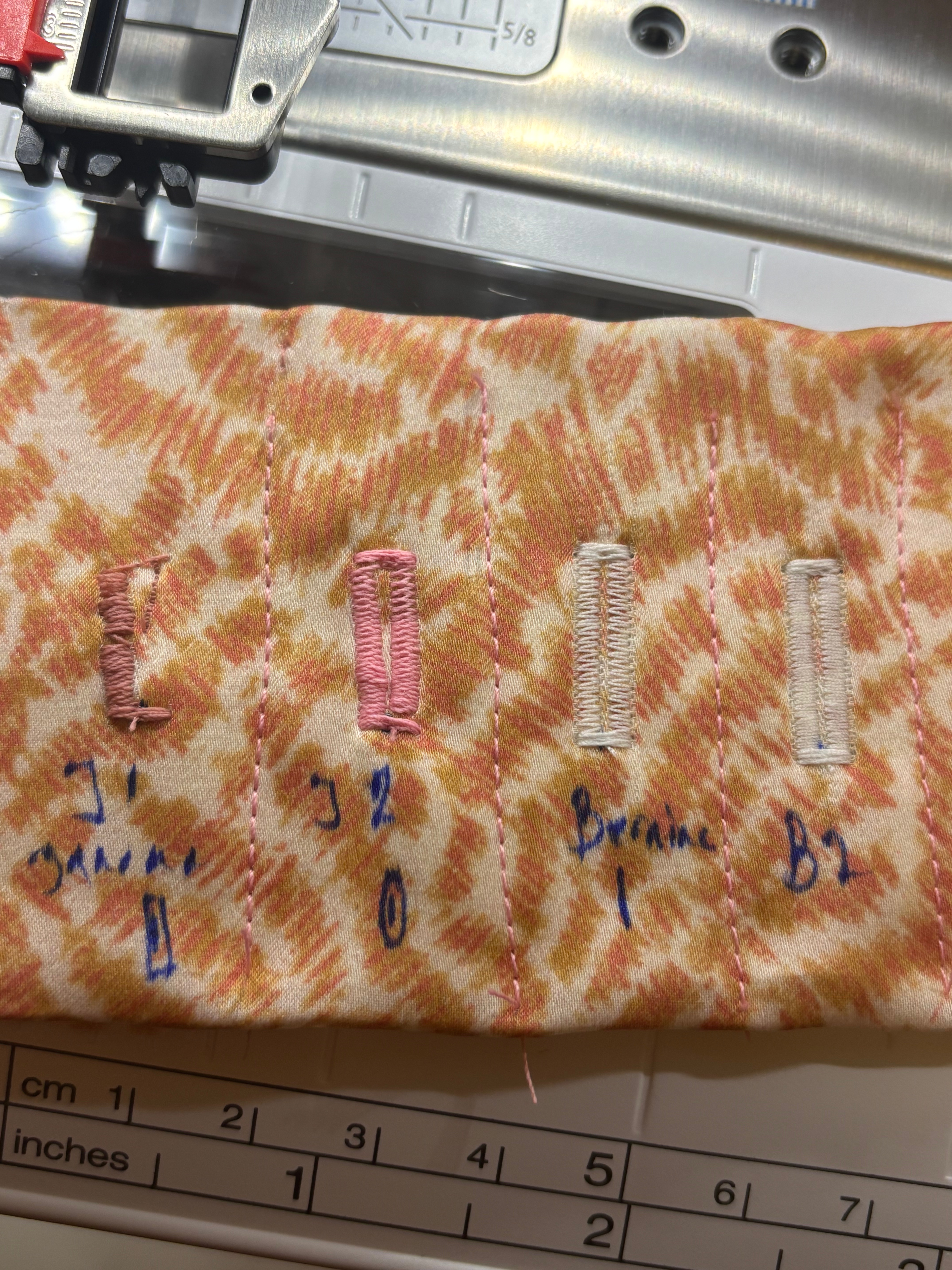

It was also the first garment I sewed on my brand new sewing machine – a belated 40th birthday present! So the new machine and I were slowly getting to know each other, and I became only more and more impressed with it as we went along. But especially – when it came time for buttonholes! I can’t believe I genuinely thought my 15 yo base model Janome would do better button holes? I was schooled – the slippery fabric got stuck in my old Janome’s feed dog, and it could barely finish a buttonhole. It only made me more impressed how well my new machine handled this tricksy fabric:

The mix of the silk twill underlined with silk CDC makes it an absolutely delight to have up against one’s skin. The two dresses, side by side:

Yeah I really need to find a better shoe match, and also not take photos in an orange dress after doing a workout so I’m not so red in the face. Dubious lighting in my work end-of-trip facilities aren’t doing me any favours here either (I swear the colour on me isn’t this hideous IRL!).

Onwards!

I did really need one more shirt dress in my wardrobe to have a comfortable number of garments in circulation. This Nani Iro Linen (“as it is” print in the pink/yellow/orange colourway) from Miss Matatabi had been a contender for my previous shirt dress pattern (McCalls 6891), but I was super nervous it wouldn’t be heavy enough or drapey enough to give the shape I so loved about the original Tencel version. Come to think of it, a wool crepe would likely work wonders! Other stash contenders all required underlining and that was something I want a long and proper break from for now.

I cut this one out over the Christmas break with the intention of sewing it up late January on a scheduled few sewing days with my Melbourne Couture Group.

I’d been very much influenced by a lot of Zoe Kratzmann rtw garments lately – they have many lovely details like matching cotton lace, eyelet, embroidery and – fagot trim. Also known as bridging, laddering and Entredeux trim. I couldn’t quite get a colour match I was happy with, but ended up including some of the white ladder trim on the sleeve and the collar.

This version came together with far more speed and enjoyment than its predecessor. And here it is, finished:

I’ve got one more new shirt dress to show you – which means my day-to-day work wear wardrobe is now replenished for the remainder of this season. Which means I can move onto a few more ‘fun’ separates that have been waiting patiently in the wings!

You are a stronger woman than me to sew with two layers of silk. Lovely results though!

Let’s just say – it’s not something I want to do again, any time soon! Far too fussy to be able to enjoy the process! Thanks Catherine :)

Well done for persisting. The Nana Iro print is very beautiful and suits the dress and you. Please tell us about your new sewing machine – I’m always looking for a machine that will make very good buttonholes.

Thanks Barbara! I took a lot of fabric samples with me to sewing machine shops to test drive them before buying – and ultimately ended up with a Bernina. The 3 series also did an excellent buttonhole – but ultimately went with a 570QE as this has the built in walking foot (which I use a lot). I can change the density of stitches in the button hole, and also the width of the stitches – so for a larger button, you can have a similarly dramatically sized buttonhole.

Thanks for the buttonhole information. What a great idea to take fabric samples to the sewing machine dealers to test out the machines.

Buttonholes come at the end of a project and can absolutely ruin something great if they are don’t correctly. They are the bane of my sewing life and I would dearly love to have a machine that really does the job without my worrying and having a fit.

I just saw a very brief video of a woman who made a spectacular woollen jacket and she took it to New York where there is a shop dedicated to making buttonholes. Nothing else. Just buttonholes. It takes them 5 seconds to make one!!! Sorry I don’t have a link to include. I’ve been to that shop and it’s amazing to see them work.

I’ve eschewed patterns with buttonholes because I’m not confident and also too lazy to make them by hand.

So, again, many thanks for the information. I’ll start researching. Fabric samples in hand…

Goodluck! And Yes I know of which you speak – I’m pretty sure Renee (aka Miss Celie’s Pants) has had her jackets ‘buttonholed’ by the same business! The outcome was fantastic! What happens when you have an industrial machine that only does buttonholes I suppose!

Both of these are wonderful. Beautiful sewing, lovely fabrics and great style. I also love the fagot lace insertion.

Thanks Elle :)